Hey everyone; very belated happy new year. One person who recently visited my YouTube channel asked for a specific wiring diagram on my solar paneled bicycle trailer. So here goes.

The kit was purchased from a Canadian company called WIKE. They are online and sell quality bicycle trailer kits. WIKE sells the main fiber glass fastener unit and stainless steel nuts and bolts. The purchaser supplies his/her own wood or aluminum tubing to build the main frame, and any additional fasteners they may need for the project. I purchased the “high-walled” kit.

Above is the finished kit. It was big fun to build and is a breeze to tow. Here’s a link to the video where the build was explained.

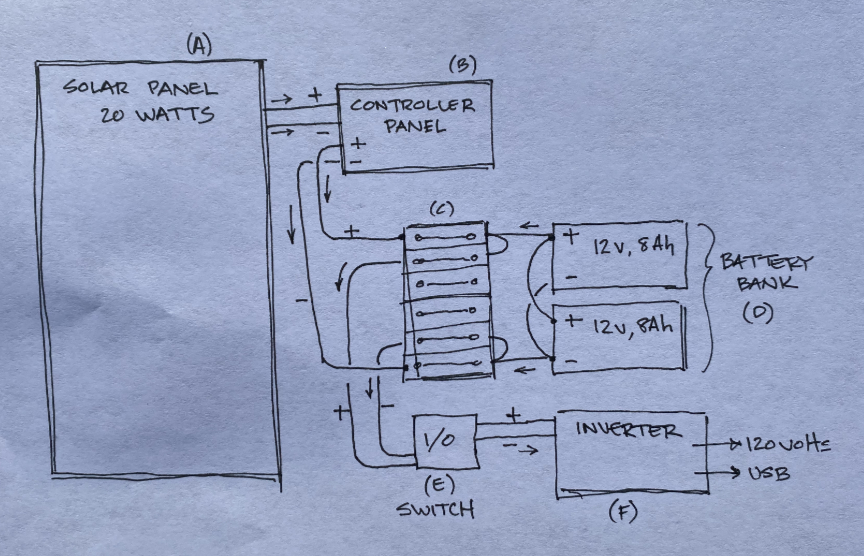

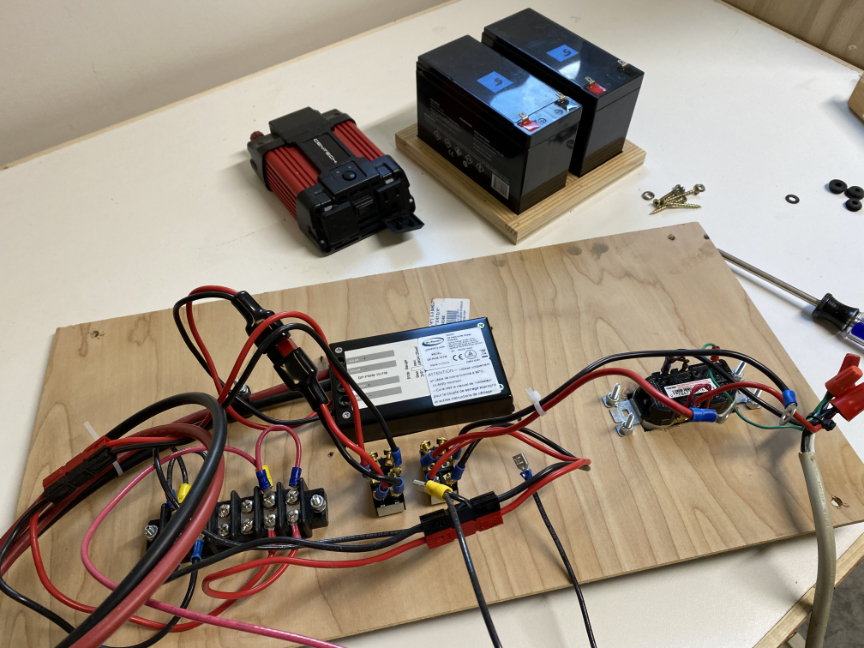

On rough gravel it is a bit noisy, but quiets down on smooth pavement. Most of noise are the wheel axles rattling inside the mounting hardware. The black panel is the controller. The switch below the controller turns the inverter on or off. Two reflectors are peel-and-stick. The tail light is battery powered. Below is a diagram of how it is all wired up.

Forgive my drawing. I know I use to draw better than this. The components are not physically positioned in this exact representation and are not to scale. However, the wiring is correct. Small arrows indicate current flow.

Components are linked together via the electrical distribution block (C). The batteries are wired in parallel (negative to negative/positive to positive.) One battery’s negative pole goes to the negative input side of the block; the positive pole of the other battery goes to the positive input side of the block. This gives me one battery of 12 volts and 16 amp hours. If you use more than one battery (i.e. three) make sure the positive pole from the battery on the end of the bank and the negative pole of the battery on the other end of the bank are connected to the controller. DO NOT connect only one battery’s poles into the electrical network, even though they are all connected in parallel. You must spread the load evenly across all batteries used.

The batteries are connected to the “input” side of the block (right side in the drawing). Two rows on the positive end and two rows on the negative end are wired together. From here the distribution block is connected directly to the controller panel (C). This is the only aspect of this setup I don’t like. The battery bank (D) is connected to the panel (C) 24/7, supplying power to the panels in order to display battery voltage, amp hours, current charging amperage, i.e. This will eventually drain the battery bank. In order to counter act this, I place the trailer in bright sunlight as often as possible. Otherwise, I disconnect the battery bank from the controller via an Anderson plug. I did have a switch installed here but decided it was not needed. (Thinking about re-installing this switch.)

From the other two live ports available on the “outgoing” side of the distribution block (C) wires go to a switch (E), then to the inverter (F). The inverter has two plugs for 120 volts output as well as USB outputs.

In conclusion, I don’t think this is the most efficient way to store/move electrical power. It might be better, for instance to simply buy another bicycle battery and connect it directly to the solar panel via the controller. However, now we are talking about another $650+ and 8 lbs. of weight. However, the system works exactly as expected. During testing I have run an electric drill on this system as well as charge my bicycle battery, using its charger plugged into the inverter. When the battery bank’s charged state drops too low, the inverter sounds an alarm and shuts the charging process down.

After using the trailer for a while I think I will eventually purchase a larger solar panel (60 watts) and add one more battery to the bank.

Anyway, thanks for visiting. Leave comments, suggestions, or advice. Take care. God bless you and yours.

UPDATE (May 4, 2021)

Since posting this story I have gone back to a two-switch system on the trailer. One switch turns the inverter on and off; the other disconnects the batteries from the solar panel controller. When in long-term storage the batteries will not be subject to constant discharge when connected. I have also re-wired an electrical outlet back into the circuit for access to 120 volts from outside of the trailer.

However, after adding the outlet and the second switch, testing indicated that the inverter is only putting out 85 to 90 volts AC. I am trying figure out why that is; all of the wiring seems correct. Maybe there are too many connections and splices. Frustrated right now, but I’ll see if I can get it to work.

Update (May 12, 2021)

Okay; I have converted the trailer back to its original, non-powered state.

After removing the rear panel I examined all of the wiring and connections and found a loose connection at one of the switches. This is why I was getting no output from the inverter.

After tightening the screw, I reconnected everything and ran a test. I was able to run a corded electric drill from the sockets wired to the inverter.

Evidently the screw had vibrated loose during road tests. This is going to be a problem over time. Connections are going to need a bolt and nut, used with Lock-Tite to keep the connections tight. Also the battery connections are not ideal as they are held together with friction.

While the system is disassembled I think I will upgrade some components. One reader suggested I should go to a larger solar panel, maybe 60 watts. Will do! I will also add another battery to the bank and perhaps switch to connection which use a bolt and nut. After I have tested the new system I will reinstall everything back onto the trailer for testing. I’ll keep you posted.